STRENGTHS

Industrial Technology

We support Daiwa's manufacturing from the design and creation of processes,

equipment, inspection devices, etc., to the maintenance of machinery and equipment.

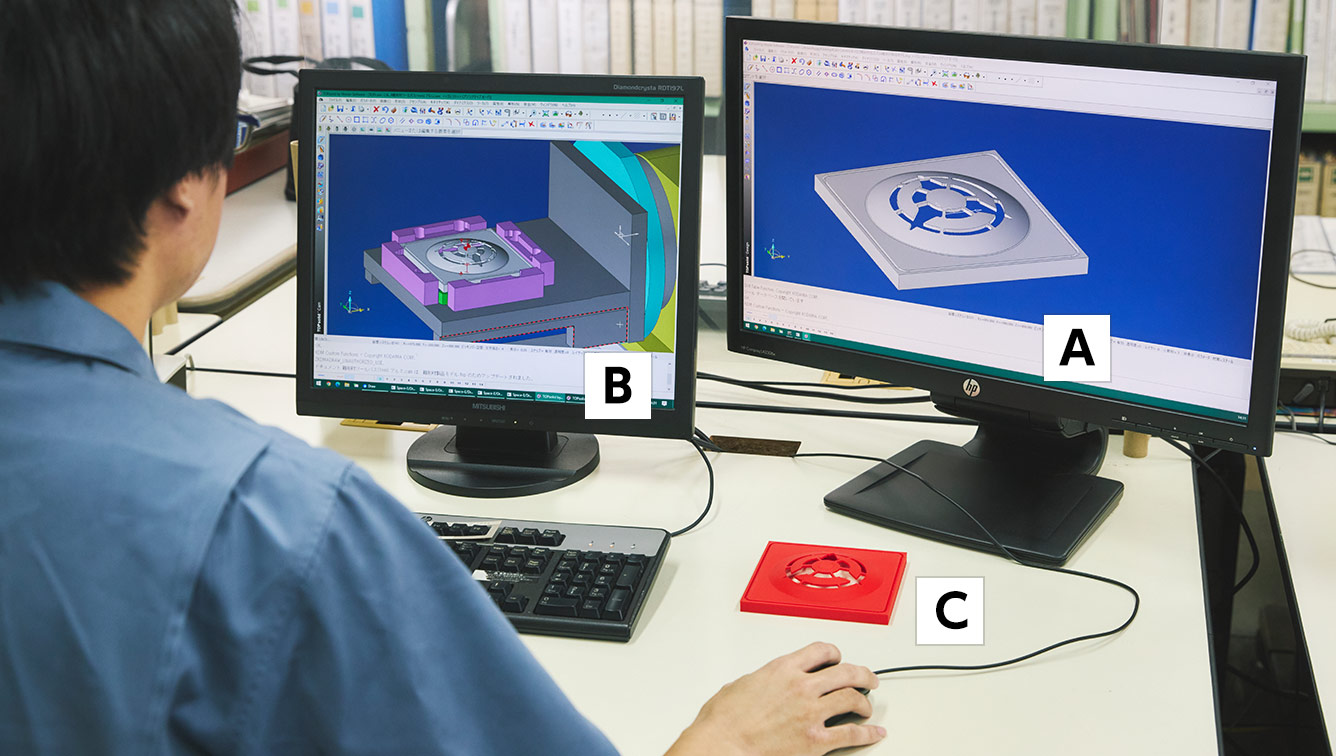

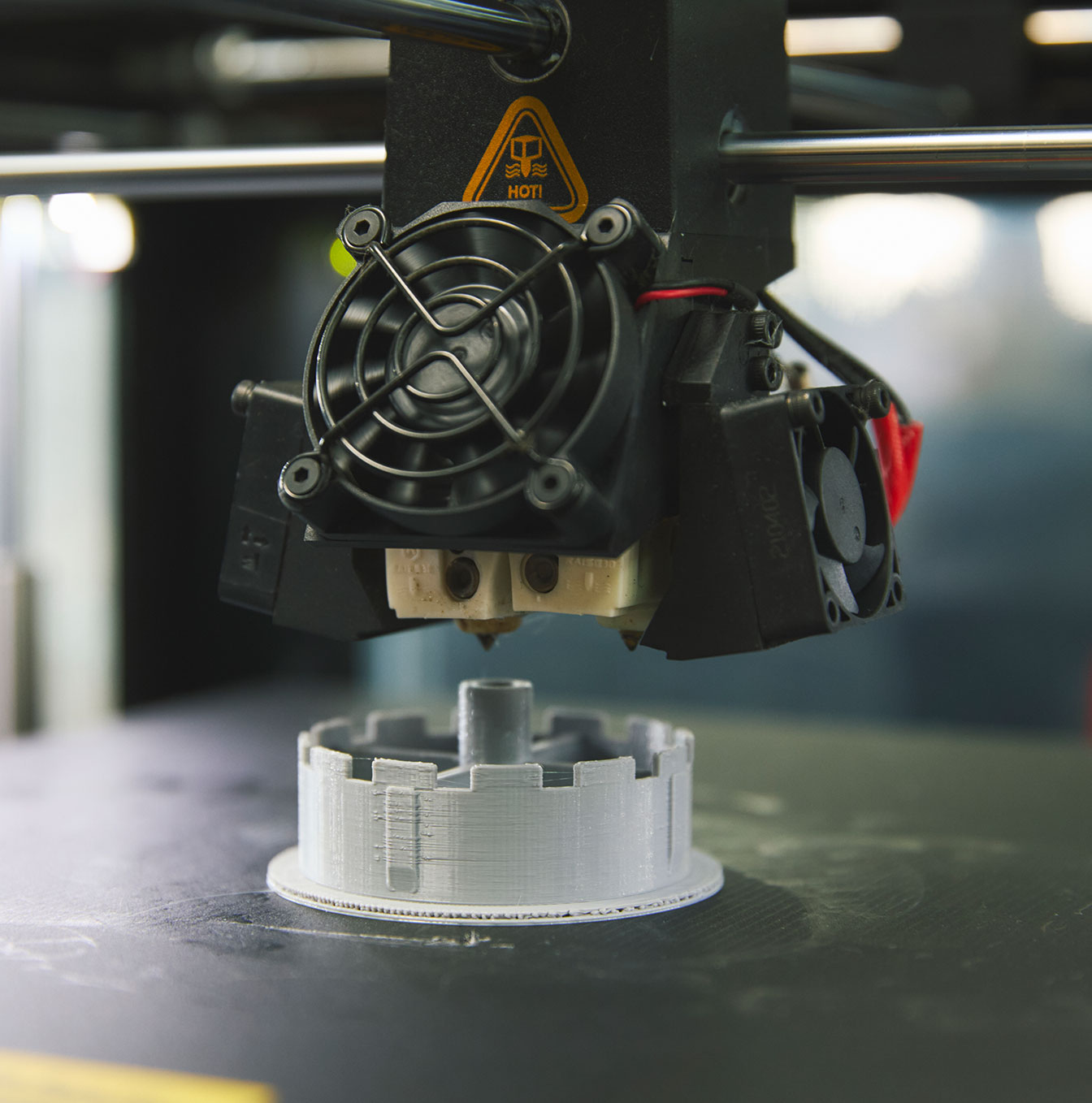

3D TECHNOLOGY /3D CAD/CAM & 3D Printers

We make full use of 3D CAD/CAM

to implement design processes efficiently and to create flawless production.

The introduction of a 3D printer has made it possible to quickly design processes and tools without mistakes using three-dimensional product samples right from the initial stage of development

A : model / B : CAM / C : manufactured product

A : model / B : CAM / C : manufactured product

3D Printer

3D Printer

ECO-FRIENDLY

SYSTEMS

/Towards the Realization of SDGs

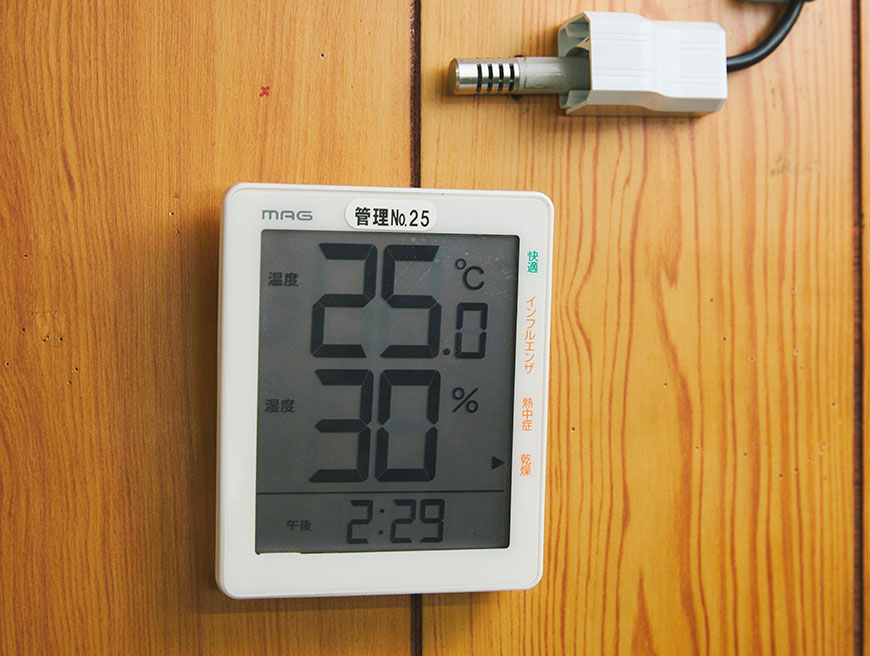

We place an emphasis on the effective use of energy

and the facilitation of a comfortable work environment.

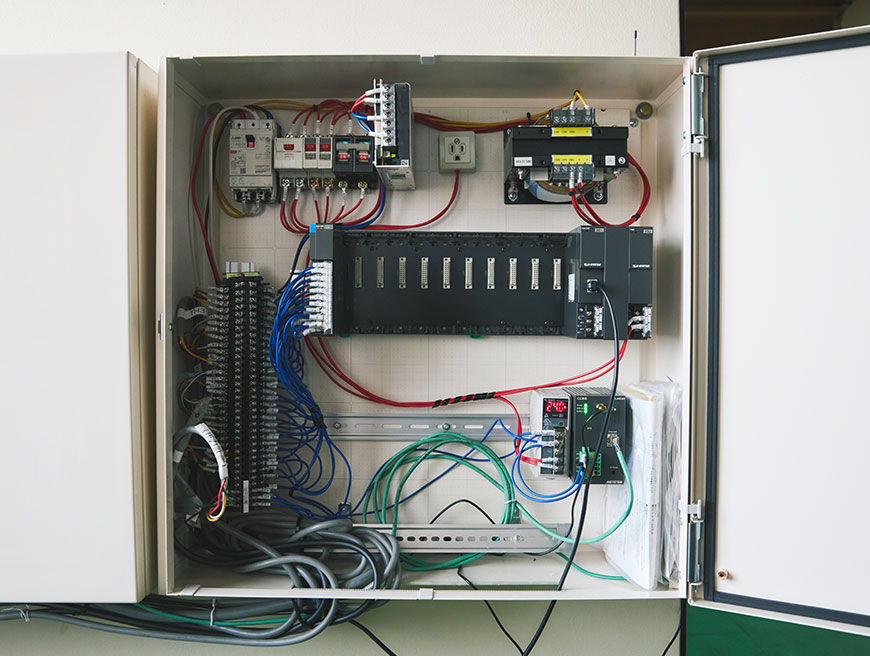

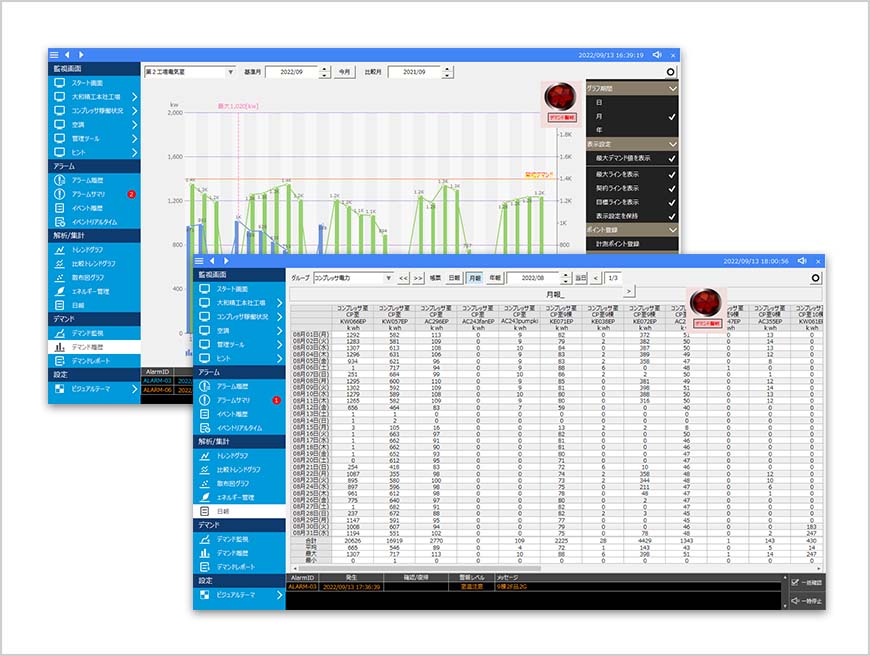

By building an in-house system, we make use of various energy monitoring systems,

remote controls, and data analysis, to implement evidence-based improvements.

(Monitoring of factory demand and power for individual compressors, temperature and humidity in work areas)

Temperature Monitoring

Temperature Monitoring

In-House Developed Energy Consumption Monitoring

In-House Developed Energy Consumption Monitoring

Power Input and Power Demand Monitoring

Power Input and Power Demand Monitoring

Air Conditioning Controls

Air Conditioning Controls

Data Collection and Analysis

Data Collection and Analysis

Compressor Power Monitoring

Compressor Power Monitoring

ORIGINAL EQUIPMENT

DEVELOPMENT

In manufacturing, it is important to have an environment where you can start from zero to craft an image that can be shared so that it can take shape.

In order to meet customer needs, the Production Technology Group pursues QCD that satisfies customers by in-house production of parts and sometimes the manufacture of specialized equipment and facilities required for full-scale production.

Automotive Parts Indentation Equipment

Automotive Parts Indentation Equipment

Cylinder Head Valve Lift Measurement Device

Cylinder Head Valve Lift Measurement Device

Track Record of

Original Equipment

- Automobile Engine Parts Machining T/M

- Automobile Engine Parts Measuring Device

- Automobile Engine Parts Burr Picking Machine

- Automobile Parts Indentation Machine

- Automobile Parts Processing Machine (Lathing, Drilling, etc.)

- Conveyor Equipment (Mechanical, Robot)

- Automobile & Construction Machinery PartsLeak Testing Machine

- Agricultural & Construction Machinery Parts Oil Injection Machine

- Agricultural & Construction Machinery Parts Boring Machine

Total Produced Units Up to Present:423 units

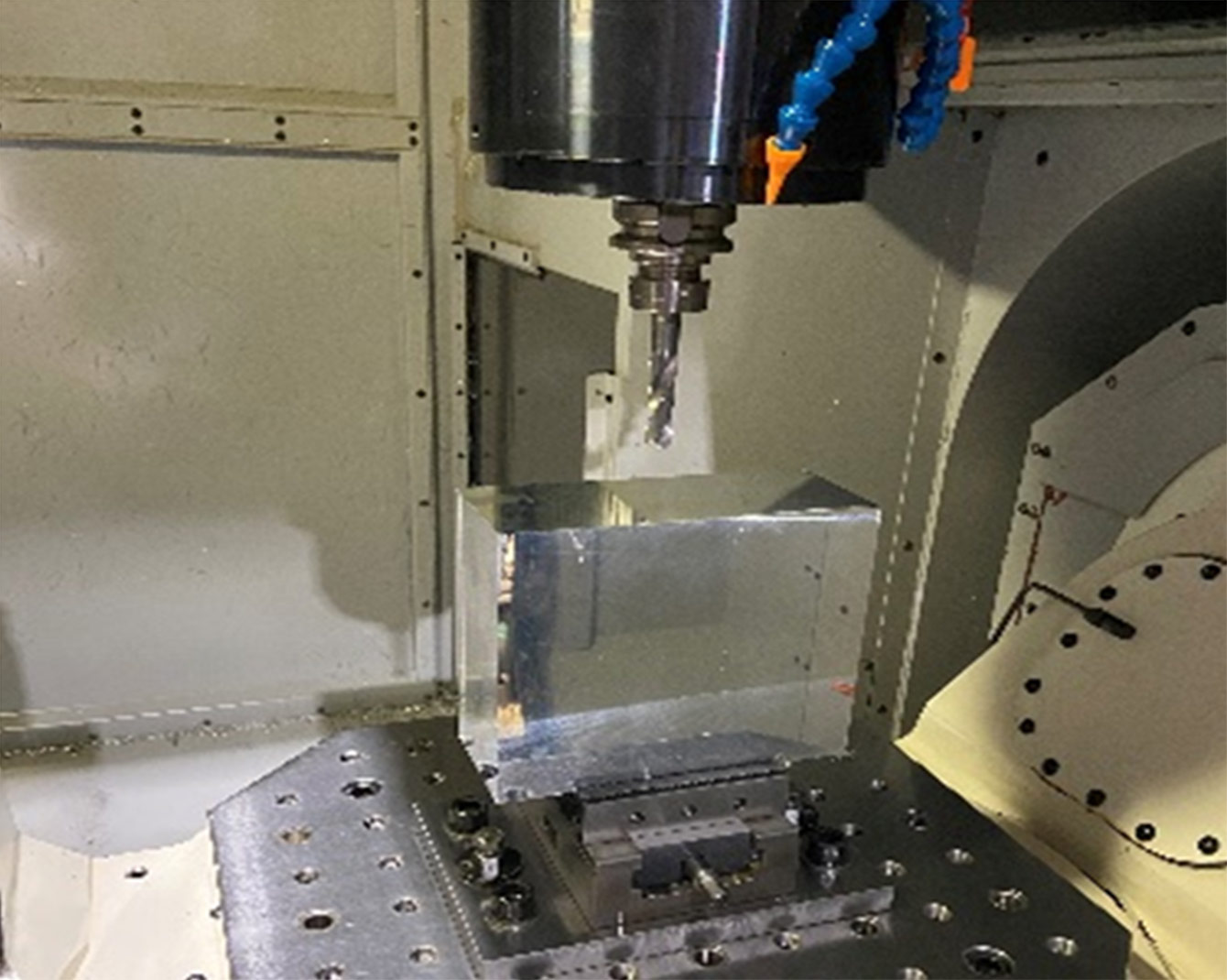

PROTOTYPE

PRODUCTION

70 years of trial production of newly developed functional parts for automotive engines and transmissions

This history proves our high level technological capabilities and commitment to quality. And this steady path is steadily moving towards a breakthrough in the aerospace industry.

Total aluminum shaving

Total aluminum shaving

Inconel total sharpening

Inconel total sharpening

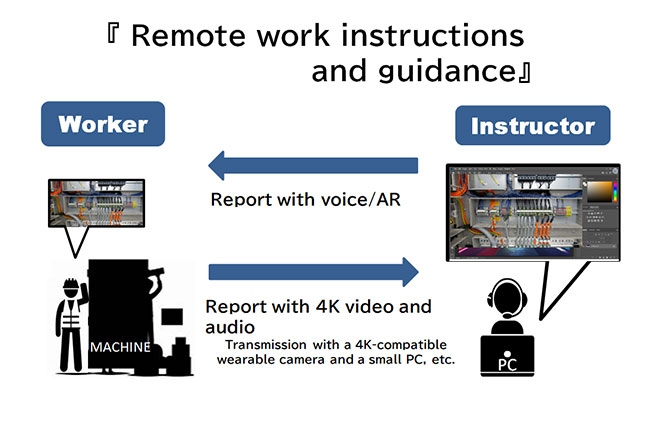

FACTORY MAINTENANCE

Each and every one of the approximately 600 facilities we own systematically conducts preventive maintenance and periodic inspections in order to fully demonstrate the performance of each unit.

We aim to quickly resolve sudden repairs through remote and timely on-site confirmation and on-site instructions.

Remote support image

Remote support image

Qualified Skilled

Personnel

- Machine Maintenance Work Certification Level 1 = 15 Engineers

- Machine Maintenance Work Certification Level 2 = 7 Engineers

(As of December 2022)

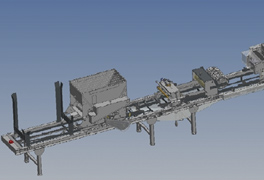

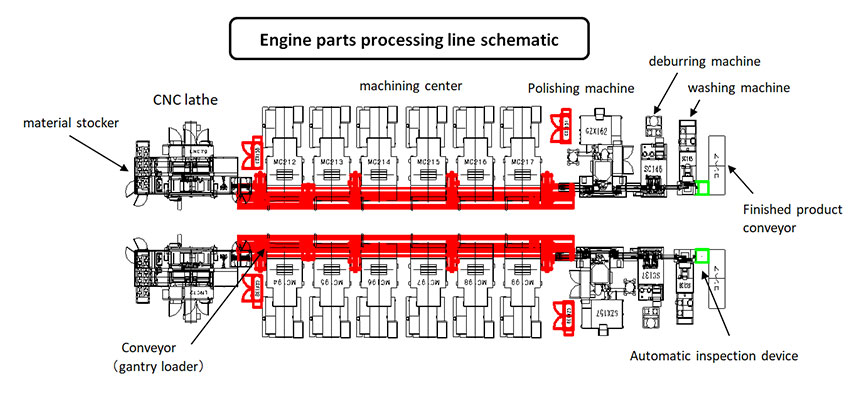

MASS PRODUCTION

KNOW-HOW

When considering mass production lines, the basis is to achieve the quality, cost, and delivery required by our clients.

In order to achieve our goals, we will build a production line by incorporating an in-line guarantee system for quality, cost-savings through in-house equipment production and labor saving processes, and utilize the FMEA method for schedule management.

In addition, we can respond flexibly and without waste to sudden increases or decreases in production.

Engine parts processing line

Engine parts processing line

Engine parts processing line schematic

Engine parts processing line schematic

CONTACT

Click here for inquiries and estimates

Japanese

Japanese