STRENGTHS

Processing Techniques

SHEET METAL

and WELDING

Our CO2 laser machine can process thin sheets up to 12mm thick.

After laser processing, high-precision bending is achieved with an NC brake press.

Another specialized equipment available is the pipe bender, which enable us to process pipes with customized shapes.

We have more than 40 years of experience with welding robots.

With a focus on automated welding of medium plates, and we also specialize in canning welding that requires oil tightness.

In addition, plasma welding is performed in the automotive industry, and TIG welding and spot welding are performed on some parts.

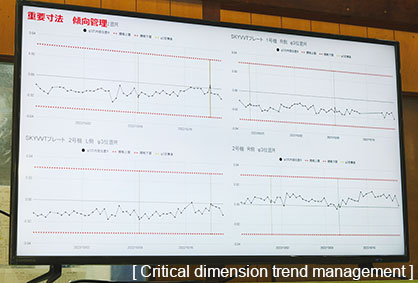

Quality control of sheet metal

processing and welding

Quality control of sheet metal

processing and welding

- Obtaining a material mill sheet and Weld part cut sample

- Thorough in-process inspection

- Carrying out 3D measurements when necessary

- Creation of QC process charts

- Implementation of inspections by in-house certified inspectors

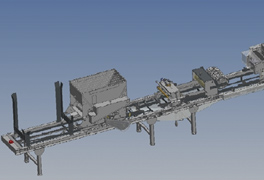

CUTTING MACHINING

We maintain a large number of CNC machines with tool holders ranging from BT30 to BT50, including cutting-edge 5-axis machines.

Various rough materials such as aluminum, ductile and stainless steel are machined with high precision, through the use of NC lathes.

□630 machining table can process workpieces up to Φ1000×1300 in size. For customized parts, we also perform broaching, polishing, and honing.

Machining quality control

Machining quality control

- Machining simulation based on programming

- Obtaining a material mill sheet

- Thorough in-process inspections

- Carrying out 3D measurements(when necessary)

- Creation of QC process chart

- Implementation of inspections by in-house certified inspectors

Qualified Skilled Personnel

- Machining Center Work Certification

Level 1 = 2 Engineers - Machining Center Work Certification

Level 2 = 3 Engineers

(As of December 2022)

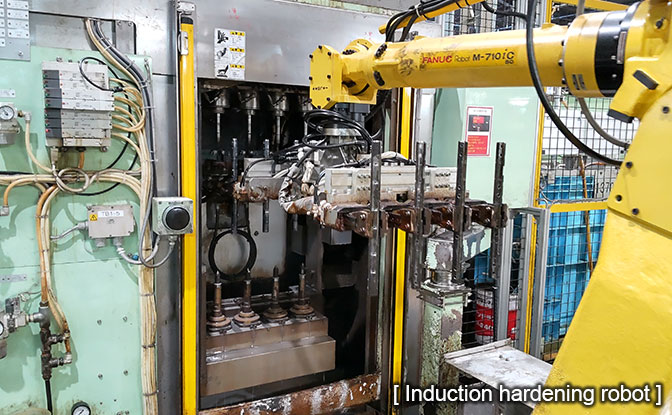

HEAT TREATMENT

We have many years of experience and achievements in "shaft induction hardening" and "laser hardening" for automobile parts.

Quality control of

heat treatment processing

Quality control of

heat treatment processing

- Hardness measurement

- Creating a cut sample and confirmation of metal

- Controlling heat treatment conditions

- Creation of QC process charts

- Implementation of inspections by in-house certified inspectors

Qualified Skilled Personnel

- Induction Heat Treatment Certification Level 1=1 Engineer

- Induction Heat Treatment Certification Level 2=3 Engineers

(As of December 2022)

CONTACT

Click here for inquiries and estimates

Japanese

Japanese