WORKS Products and Services

2022.12.27

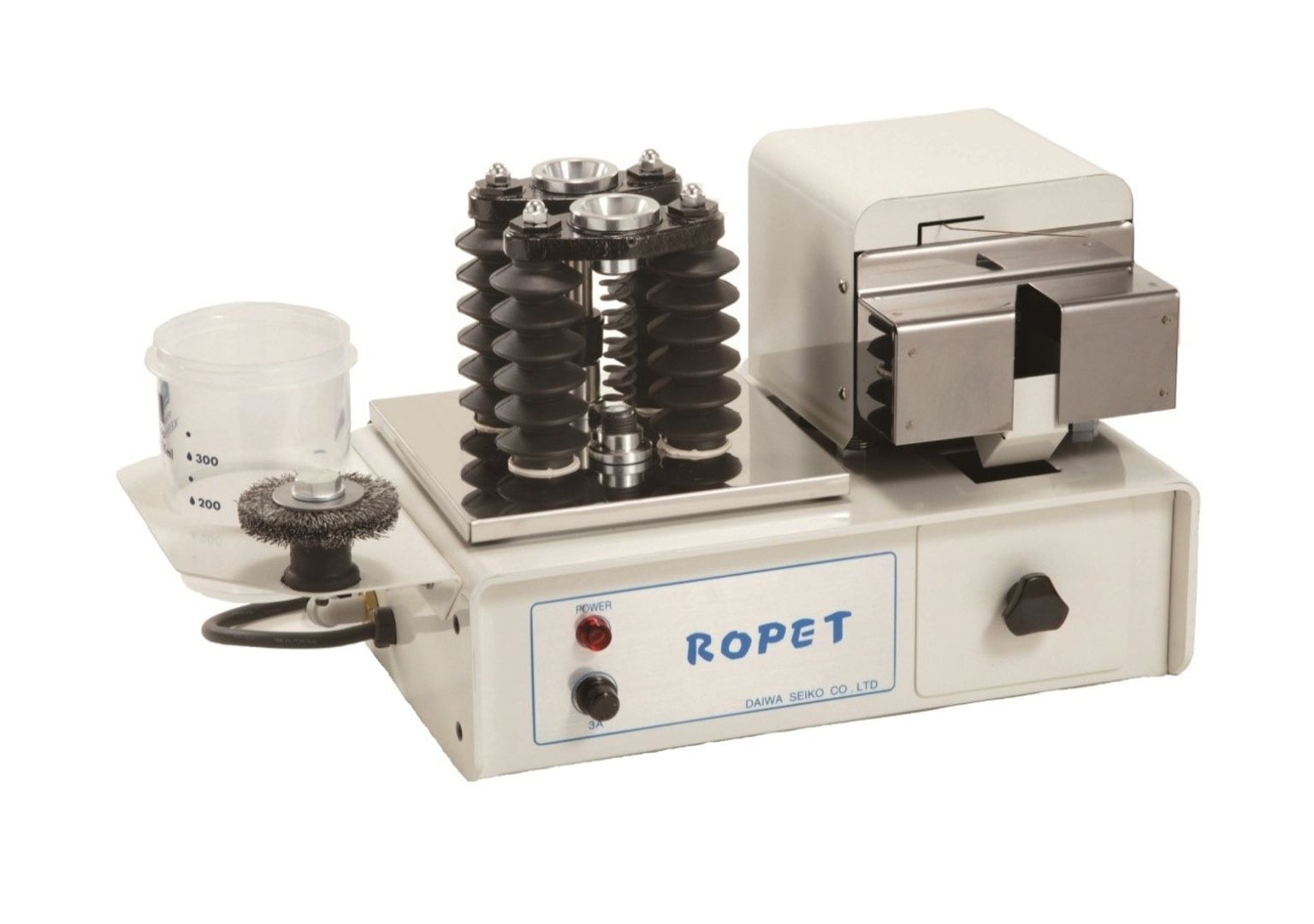

ROPET, a Spatter-Removal Robot Originally Made to Improve In-House Welding Productivity

| Industry | Factory equipment |

| Division | In-house product |

| Weight | 11kg |

| Dimensions | 440mm×195mm×232mm |

| Product name | ROPET |

| Product Summary | Prevents and removes spatter from adhering to welding nozzles |

| Number of production | 200 units/year |

1. Development

At Daiwa Seiko’s own factory, the welding robot had spatter adhered to the nozzle, which deteriorated the welding quality. Each time this happened, the automatic operation had to be stopped for the operator to remove the spatter.

“Is it possible to create a cleaning machine equipped with spatter removal, anti-adhesion agent application, and wire cutting functions?”, “Can we program it into the automatic operation process of the welding robot?”, were the questions we asked that lead to the development of this product.

2. Composition

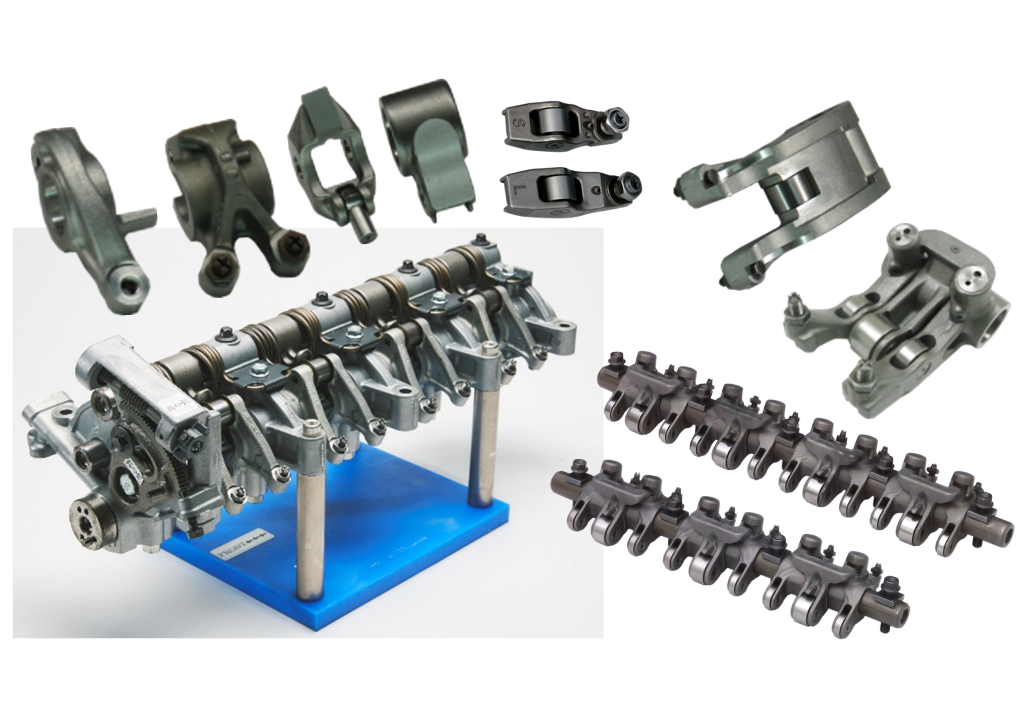

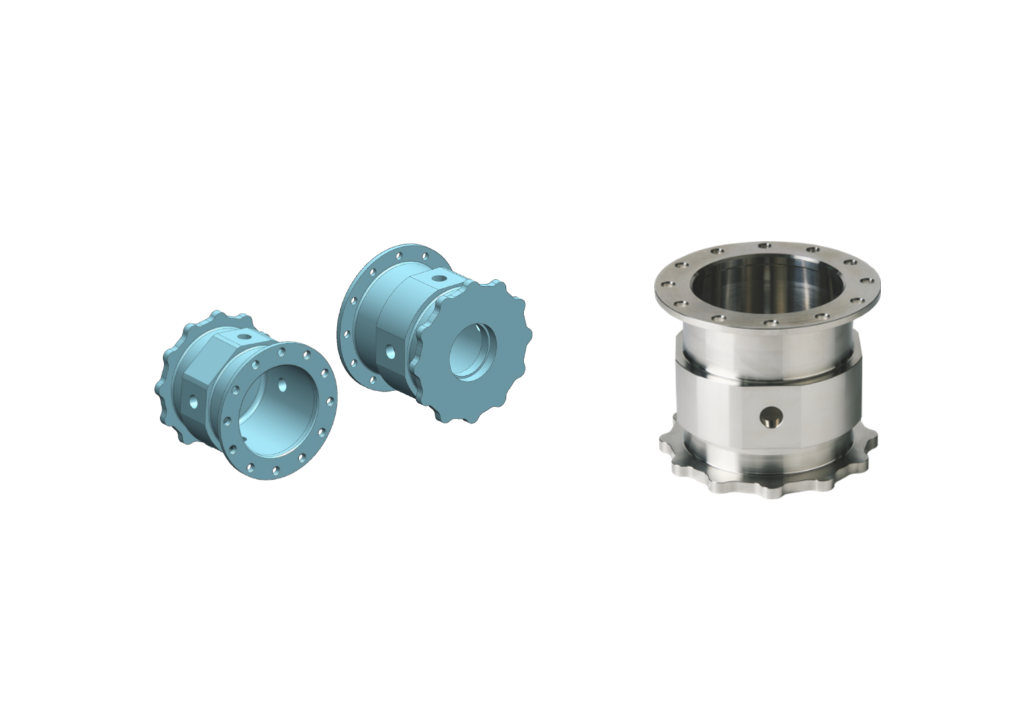

Thin sheet metal (iron, stainless steel), ground products (iron), brushes, electric parts, etc.

3. Specifications

- To clean spatter from welding nozzle without using manpower. In addition, the rotating cutter improves the quality of the appearance by trimming the tip of the welding wire.

4. Manufacturing Process

At Daiwa Seiko, the following process is carried out :

Parts Procurement ➡ Acceptance Inspection ➡ Assembly ➡ Finished Product Inspection ➡ Shipment

5. Other Specifications

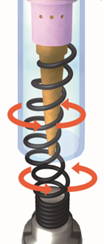

① Patent

- Adoption of eccentric spring type drill

- Use of powerful suction device

② Adoption of custom specifications based on customer requests

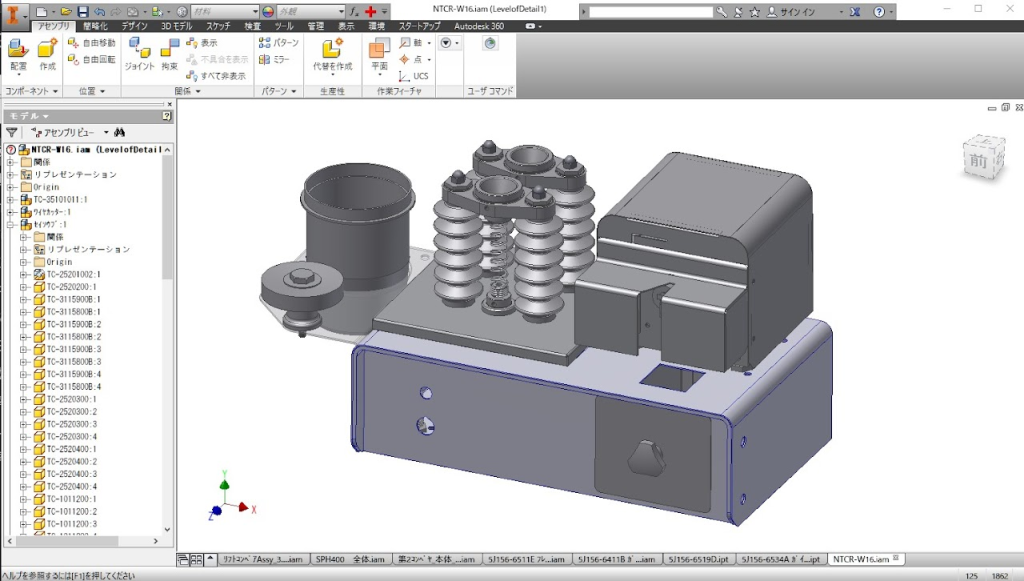

6. CAD Software Used

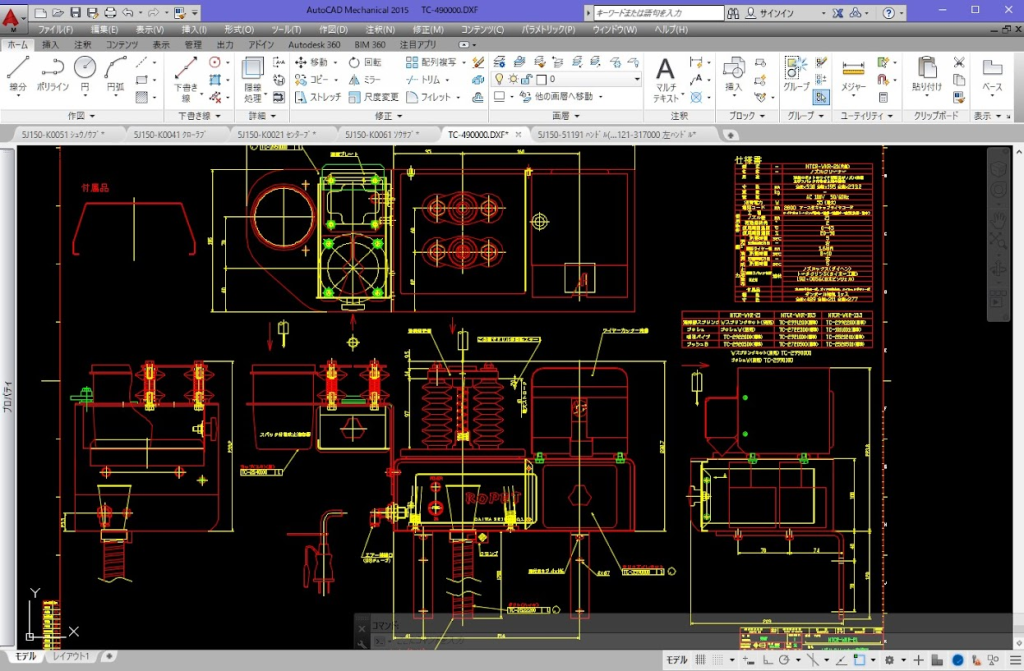

3D:Inventor 2D:AutoCAD Mechanical

Please feel free to contact us for technical consultation.

Japanese

Japanese