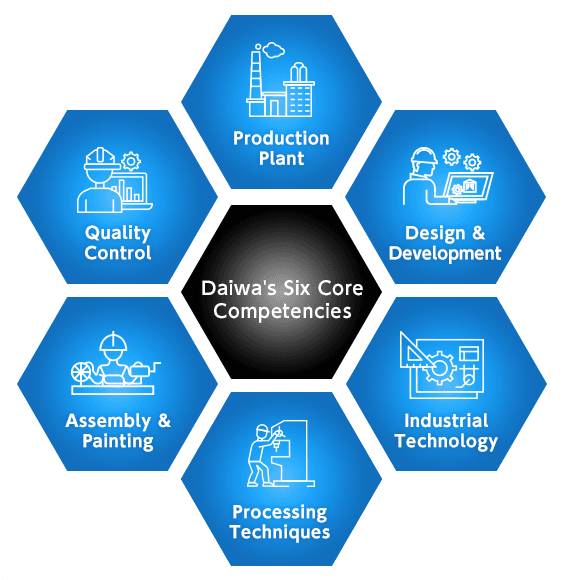

STRENGTHS

Quality

QUALITY ASSURANCE

Daiwa Seiko Quality

Acquired ISO9001 Certification

"Quality Assurance System Based on ISO9001"

We have a quality assurance system based on ISO9001 standards to maintain and continue high quality in design, processing, assembly, inspection, testing and shipping processes from single parts to assembled products, OEM and ODM products.

We provide reassurance and reliability through thorough quality control.

QUALITY MANAGEMENT

Keen awareness and a flawless management system lead to excellent quality

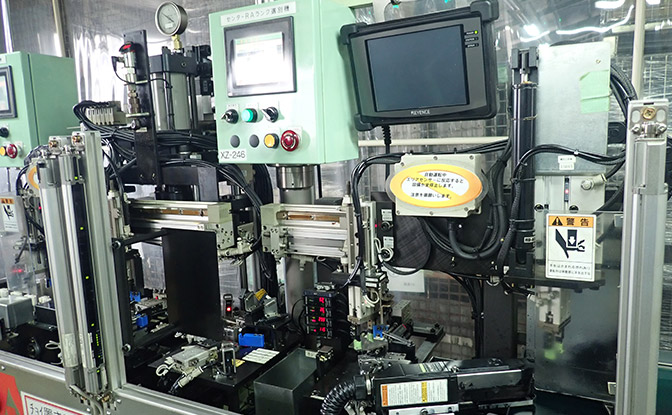

At Daiwa Seiko, we use the belief that "the next process is the customer" as the basis for our flawless inspection system which makes use of control protocols for everything from materials to finished products, and we perform in-house development and include specialized inspection machines, image processing, and laser equipment in the production line to satisfy product specifications and applications.

In-Line Inspection

In-Line Inspection

- In-line inspection equipment developed and manufactured uniquely for each product function and characteristic is used to guarantee all products.

- Functional assurance of automobile engine valve mechanism

- Total inspection equipment for appearance and dimensions incorporating image processing and laser equipment

Periodic Inspection

Periodic Inspection

- Establishment of an inspection system based on control protocols, and used for base material inspection up to completed product inspection

- Stable quality by deploying statistical process controls that utilize IOT technology

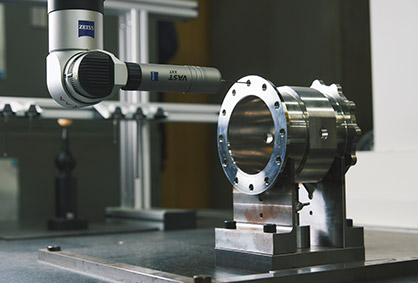

Quality Guarantee

through Inspection Equipment

Quality Guarantee

through Inspection Equipment

- 3D scanner

- 3D measuring instrument

- Surface roughness meter

- Shape measuring instrument

- Roundness measuring instrument

- Universal testing machine etc.

CONTACT

Click here for inquiries and estimates

Japanese

Japanese